CHALLENGE TO THE EXCELLENCE

The 21st century is regarded as the era of high performance engineering plastics such as PPS, PSF, PES, LCP, PEEK. In anticipation of the times to come, we have devoted ourselves to enhance the compounding technology on them for the last decade.

For instance, to reinforce them with glass fibers or mineral fillers is what we are good at.

We are confident of being able to adequately knead and modify any high performance engineering plastic according to customer’s requirements.

In order to produce a quality compound, sophisticated extrusion technology is needed.

In parallel with it, R&D on the material for such extruder’s parts as screw element, barrel or innovative expertise on pelletizing after extrusion plays an important role.

We, therefore, have been continuously making strenuous efforts so far to actively accumulate those know-how.

This is the secret for success to survive the future in the compounding arena.

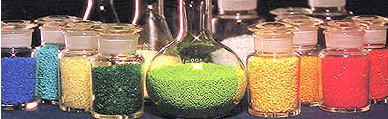

CUSTOM COMPOUNDING

We are custom compounders who produce a quality plastic compound based on a resin supplier’s formulation and supply one onto the market under their label. As a so-called OEM manufacturer, we have been doing our best to supply a high quality compound with high cost performance for the last 50 years.

Our production capacity per annum reaches 210,000 tons. Dreaming of the best Japanese compounder to be, we have been engaged in compounding almost all kinds of thermoplastics ranging from a commodity plastic resin to a high performance one since our foundation in 1964.

In part, as color compounders, in part, as full compounders, we have served the plastics industry by utilizing the most sophisticated compounding technology. As is often the case with the Japanese compounding business, we are willing to accept any lot order from small size to large one.

In reference to the number of advanced twin screw extruders installed, we are proud to be one of the best three Japanese compounders.

What we aim at is to be an all-round player with high technology in the industry concerned.

PROPRIETARY COMPOUNDING

The times have come, when custom compounders should be transformed into proprietary compounders whose products are developed on their own and supplied under their own label.

The reason is simple. As a current trend, resin suppliers scramble to repeat M&A one after another to get bigger and stay alive. The bigger they grow, the more they concentrate on large volume business, which means, small business is separated from them.

So, the market needs companies who handle a small lot size or a low volume special product. This phenomenon highlights the necessity of proprietary compounders who accept the unprofitable business for resin suppliers. Strangely, few proprietary compounders exist in Japan. However, as you know, a lot of compounders of this nature are active in the western world. They buy neat resins from resin suppliers, then process and sell compounds on their own brand.

There are cooperative and complementary relations between the both groups. Resin suppliers, of course, appreciate the important role of proprietary compounders.

Now is the time to act for us Japanese compounders. We have to adapt to the changing realities.

The customers necessitate the advent of proprietary compounders. “From custom compounders to proprietary ones” This is our catch phrase and what we dream of becoming.